PVC Compound for Powder-slush forming

(Tatsuta Slush Compound) is Powder-Slush compound for automotive interior skin developed by Tatsuta Chemical Co., Ltd.

(Tatsuta Slush Compound) is Powder-Slush compound for automotive interior skin developed by Tatsuta Chemical Co., Ltd.

TSC is PVC compound with excellent physical properties, formability developed by Kaneka’s resin development technology and our company’s formulation technology.

■ Product properties

| Material with no need of coating comparing to TPU series and no harm to environment | |

| This material can widely respond to from high feel quality grade up to high heat resistance grade. | |

| Color matching acceptable for black, brown etc. | |

| Most suitable for Powder-Slush with high flowability. |

| ※ | The above results are typical physical data, but not guaranteed. |

|---|

■ Examples of application

| Automotive skin material for instrument panel |

Basic property

Basic property

| Item | High Heat Resistance Grade | Heat Resistance Grade | High Feel Quality Grade | Evaluation method | |||

|---|---|---|---|---|---|---|---|

| TSC-6101 | TSC-2101 | TSC-1101 | |||||

| Powder Physical properties | Angle of response | 33 | 31 | 31 | Rotating spindle method | ||

| Apparent density(g/ml) | 0.58 | 0.59 | 0.63 | JIS K7365:1999 | |||

| Skin material | Density(g/cm3) | 1.20 | 1.17 | 1.19 | Water substitution method | ||

| Hardness | 51 | 61 | 73 | Shore A | |||

| Feel | Very soft | Soft | Smooth | Company method | |||

| Fogging(%) | 0.3 | 0.2 | 0.1 | 100°C x 20hrs. | |||

| Glass transition point(°C) | -20 | -13 | 1 |

Dynamic viscoelasticity tanδpeak value |

|||

| Tensile Strength(MPa) | 85°C | 1.6 | 2.7 | 1.8 |

JIS K6251:2010 Dumbbell shape :Dumbbell No.3 Speed :200mm/min. |

||

| 23°C | 8.4 | 11.3 | 12.2 | ||||

| -20°C | 15.9 | 19.5 | 21.7 | ||||

| Elongation(%) | 85°C | 507 | 407 | 588 | |||

| 23°C | 431 | 323 | 308 | ||||

| -20°C | 213 | 241 | 117 | ||||

| Tear Strength(N/mm) | 30 | 34 | 49 | JIS K7128-3:1998 | |||

| Surface property | Scratch resistance | No abnormality | No abnormality | No abnormality | 200gf | ||

| Abrasion resistance | Dry | No abnormality | No abnormality | No abnormality |

200gf × 100times friction side 10mm×10mm |

||

| Wet | No abnormality | No abnormality | No abnormality | ||||

| Chemical resistance | Alcohol | No abnormality | No abnormality | No abnormality | 23°C × 3hrs | ||

| Gasoline | No abnormality | No abnormality | No abnormality | ||||

| Car wax | No abnormality | No abnormality | No abnormality | ||||

| Environmental property | Heat loss(%) | 0.50 | 0.50 | 0.30 | 110°C × 168hrs | ||

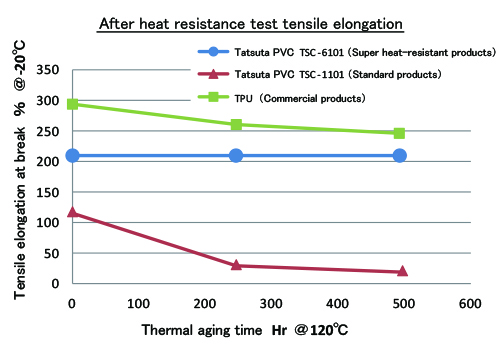

| Laminated material Physical preperty(*1) | Environmental property | Heat resistance |

Elongation(%) (-20°C ) |

210 | 68 | 26 |

120°C × 250hrs JIS K6251:2010 Dumbbell shape :Dumbbell No.3 Speed :200mm/min |

| ※ | Surface material thickness:1.0 mm |

|---|---|

| ※ | The above results are typical physical data, but not guaranteed. |

| *1 | Laminate with. expanded polyurethane(0.16g/cm3) sheet |