TM

TM

Inner embossed decorative sheet

TM is high quality decorative sheet of Tatsuta Chemical Co., Ltd. with excellent design performance and formability.

TM is high quality decorative sheet of Tatsuta Chemical Co., Ltd. with excellent design performance and formability.

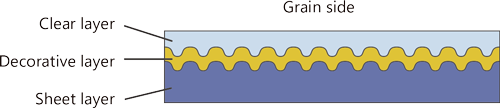

Inside of thin clear sheet, inner-embossing is done by our company’s original process technology.

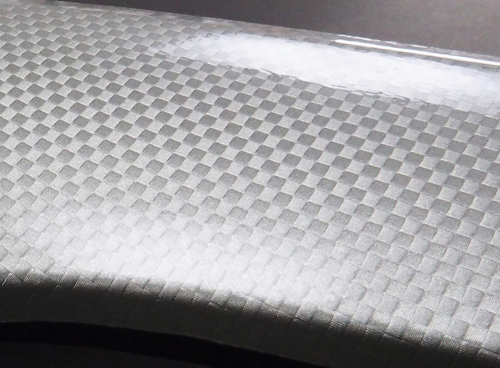

3 dimensional texture design can be achieved keeping surface smoothness and this fascinating sheet makes you feel spontaneously hold by hand.

Coating after forming is not necessary with harmless affect to humans and environment.

■ Configuration of  TM

TM

■ Compatibility of high quality design and excellent formability.

| Even with flat surface, Inner-embossing effect brings in excellent design expression | |

| 3 dimensional feeling, Changing feeling, Depth feeling | |

| Exact shape follow-up action | |

| Excellent inner embossing retention |

■ Forming process(Covering) method

| Insert molding |

■ Examples of application

|

Automotive interior panel Panel face material of fully-fitted kitchen(system-kitchen) etc. |

TMBasic property

TMBasic property

| Item | Evaluation result | Evaluation method | |||

|---|---|---|---|---|---|

| High temperature property | 160°C Tensile strength(N) | MD | 1.50 |

JIS K6251:2010 Dumbbell shape :Dumbbell No.1 Speed : 200mm/min. |

|

| TD | 1.56 | ||||

| 160°C Elongation(%) | MD | 253 | |||

| TD | 271 | ||||

| Heat shrinkage(%) | MD | -0.9 | 100°C x 1hr | ||

| TD | -0.9 | ||||

| Environmental property | Light resistance*2 | 300 hrs | 4.5 |

Ultraviolet light Fade-o-Meter Black panel temperature=83°C Light irradiation only |

|

| 400 hrs | 4 | ||||

| Heat resistance | No appearance abnormality |

95°C×5hrs→R.T.×0.5hr After 2 cycles, to observe surface condition. |

|||

|

Environmental cycling (Heat, Cold and Humidity) |

No appearance abnormality | *1 | |||

| Haze(%) | 0.9 | ||||

| Surface property*2 | Abrasion resistance | Gakushin-type abrasion tester | 4 |

500 gf x 3,000times Friction side 20mm x 20mm |

|

| Traverse abrasion test | 5 |

1kgf x 10,000times Friction side 20mm x 20mm |

|||

| Chemical resistance | Sheet cleaner | 5 |

Gakushin type abrasion test 200gf x 200times Friction side 20mm x 20mm |

||

| Synthetic sweat | 5 | ||||

| Benzine | 4.5 | ||||

| Fog protection agent | 4.5 | ||||

| Pencil hardness | F - H | JIS K5600-5-4:1999 | |||

| *1 |

-30°C×2hrs→R.T.×0.5hr→90°C×2hrs.→R.T.×0.5hr→50°C,R.H.95%×15hrs→R.T×0.5hr Observe surface condition after 3 cycles of above series of testing. |

|---|

| Grade | Degree of abnormality |

|---|---|

| 5 | No admitted |

| 4 | Slightly admitted but not noticeable |

| 3 | Slightly but clearly admitted |

| 2 | Slightly remarkable |

| 1 | Fairly remarkable |

| ※ | The above results are typical physical data, but not guaranteed. |

|---|