Skin material for automotive interior part of Tatsuta Chemical Co. Ltd. respond to each car manufacturer’s specification and many methods of forming process.

Since our products were adopted for the first time as automotive interior materials in 1963,we have responded to the needs of hard change by respective proper techniques of formulation , coating , embossing , laminating.

Skin material for automotive interior part techniques of Tatsuta Chemical Co., Ltd. is still developing not only in Japan but also all over the world.

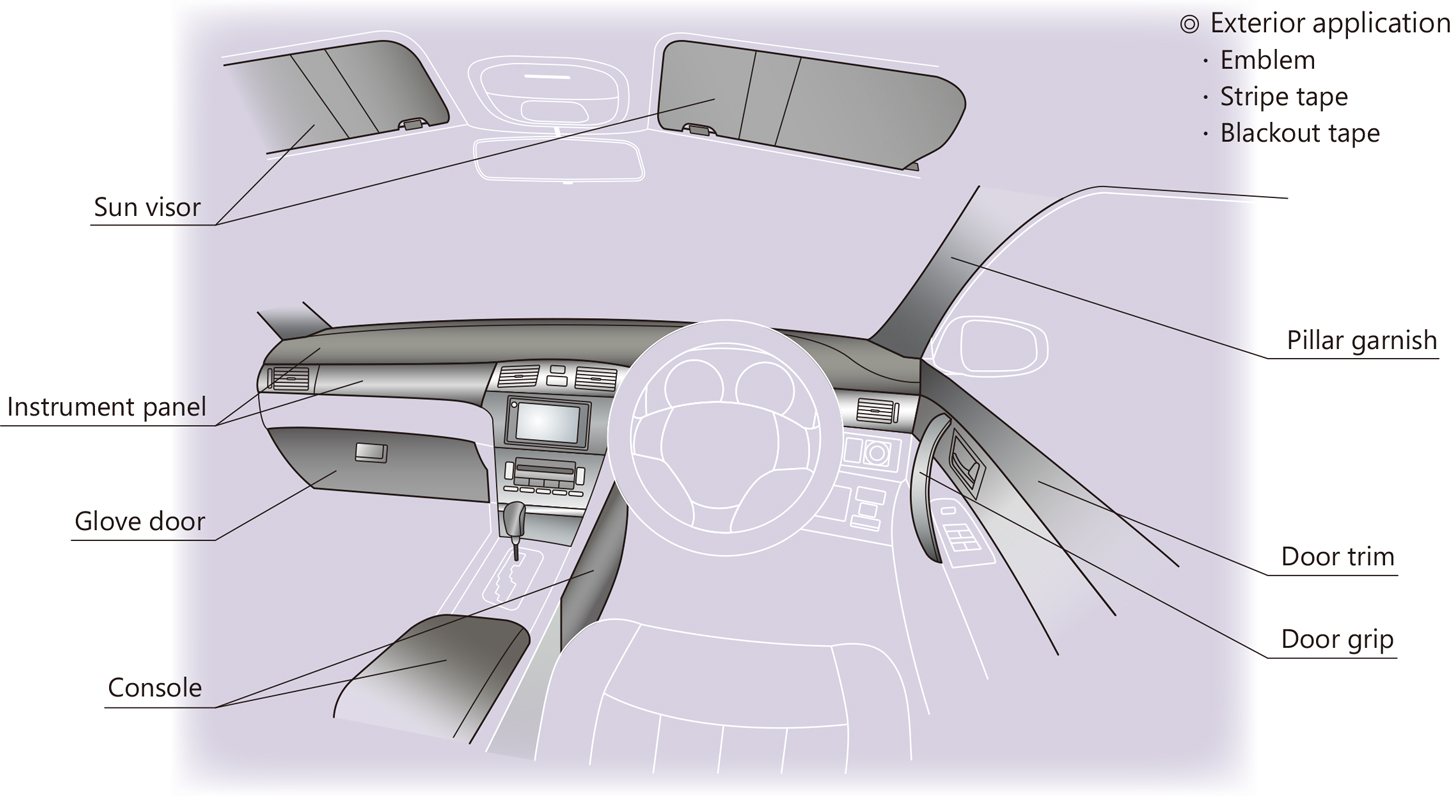

■ Examples of application

Our products have been adopted by Nationwide Japanese Car Manufacturers and Overseas Car Manufacturers.

Here even in your car, you can find  ’s product.

’s product.

■ Various forming process methods

Cast urethane after male , female vacuum forming. Insert male , female vacuum forming.

Simultaneous SPM molding, SPM molding after male , female vacuum forming.

Tatsuta Chemical Co., Ltd. continues developing skin materials having both function and design by combining excellent each technology.

| Formulation Technology | Durability, Formability, Environment countermeasure |

|---|---|

| Surface treatment Technology | Design performance, Durability |

| Processing technology | Durability, Formability, Design performance |

| Recycle technology | Environment countermeasure |

| Design | Design performance |

■ Each item of physical properties

| ※ | The following physical properties respond respectively to each Car Manufacturer specification and each process. |

|---|---|

| Tensile strength, Elongation, Tear strength, 50% modulus | |

| Scuff and Mar resistance, Anti-stick property, Abrasion resistance, Dry cloth abrasion tinting property , Wet cloth abrasion tinting property | |

| Light resistance, Cold resistance, Volatile loss, Haze, Heat aging resistance, Heat shrinkage | |

| Chemical resistance, Odor testing |